Week 18

- Category: Project Development

- Sessions Date

- Assignment:

- Tracking Progress of Work Completed and the Work that Needs to be Completed

Week Assignment

The main objective for this week was to complete my final project and then getting it all ready for the final presentation. The elements that have been completed and the things that need to be resolved. The electronics part has been completed thanks to the assistance provided by Suhas when he was in Bhutan. Everything functioned well except for some errors in the ESP due to hardware damage, which was resolved. One of the components that we had to include for this assignment was to note the things that we learned in the duration of Fab Academy. This made me have mixed feelings. I was happy that I would be graduating soon, however was sad that the course was coming to an end. Thank you Fab Academy.

The completion of the final project was done by tracking my progress by using the following questions:

- What tasks have been completed and what task remains

- What’s working? What’s not?

- What questions need to be resolved?

- What will happen when?

- What have you learned?

Tasks Completed

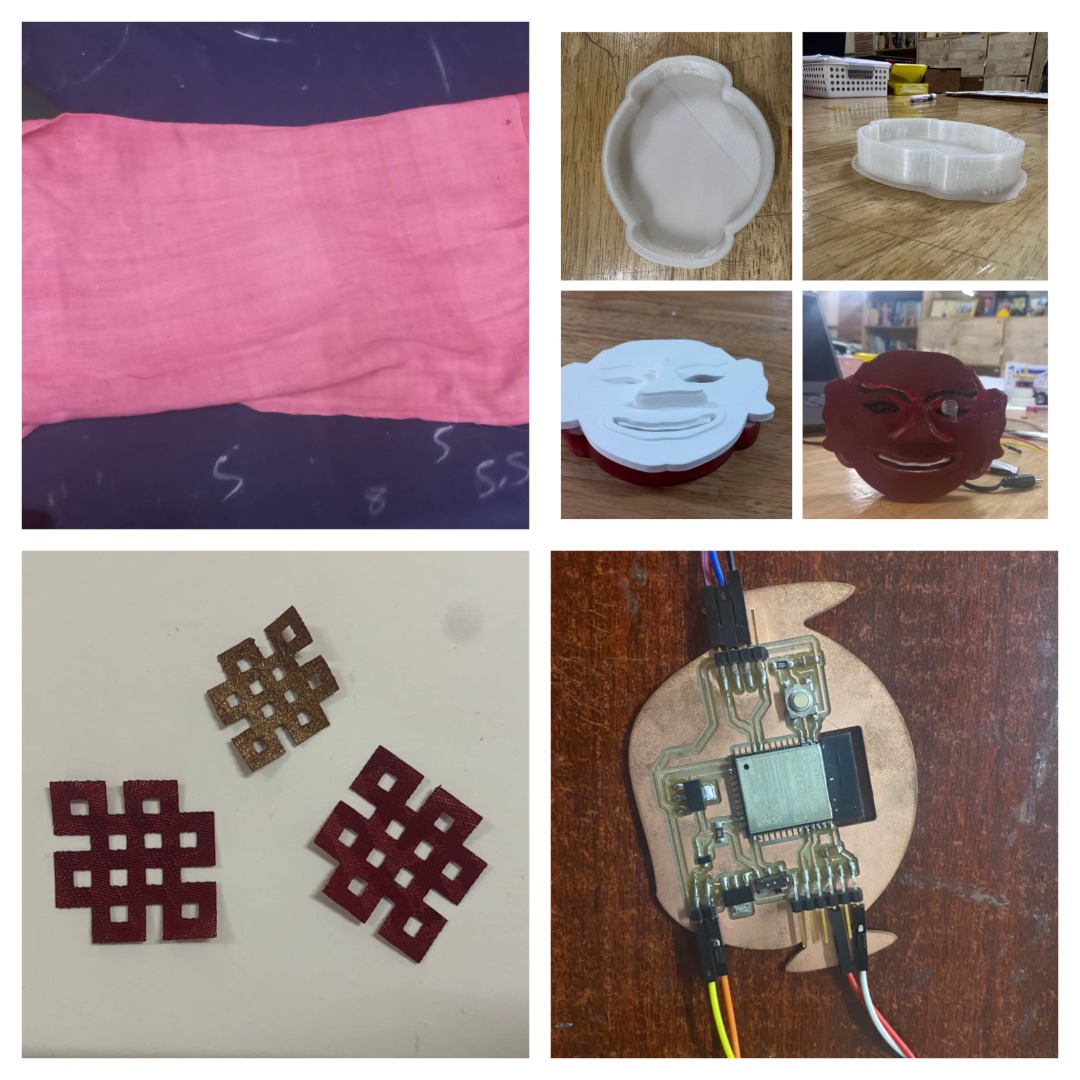

- Dyeing of the raw silk using natural dye

- Programming the LDR (Light Detector Sensor) to respond based on the intensity of the light detected

- 3D printing the controller case for the ESP board and other LDR

- PCB milling the board

- Laser Cutting the Design to be attached to the dyed rachu

- Soldering the Electronic Components into the PCB milled board

Tasks to be Completed

- Stitching the output LED to the scarf

- Assembly of the components in the controller case

- Testing the electronic components of the to see if the components provide the desired result

- Beautification of the product

Working

- Programming of the system worked based on the requirement

- PCB milling of the board

- Providing an input of 5V is best fit for making the LED light up. Any input greater than that causes the components to burn

- Everything worked as per the initial plans for the project

- It was recommended by Suhas to use Phototransistors instead of LDR. However, due to constraint in time I was not able to make the changes recommended.

- The functional parts for my project will not be a problem. Since the project is powered by a 5V power supply, there seems to be no problem with the functionality under these conditions.

| Sl No. | Description | Date |

|---|---|---|

| 1 | Stitching the output LED to the scarf | 3rd June-4th June |

| 2 | Assembly of the components | 5th June-6th June |

| 3 | Testing the components | 7th June-8th June |

| 4 | Beautification of Product | 9th June-10th June |

| 5 | Presentation Preparation | 11th June |

| 6 | Project Presentation | 13th June |

What have you learned?

- From the Fabacademy I have learned about electronics and coding especially. Being from a non-technical background the course has helped me gain lots of technical knowledge. I intend to learn more about the things taught through the open-source Fabacademy page.

- Though 3D printing and designing was something I had already learned while working in Fablab Bhutan, through the Fab Academy I learned how it can be utilized in different ways starting from everyday utilization to more technical usage

- Fabrication of Circuit board by PCB milling

- Learned a lot about LDR sensor and its alternatives. How it can be used to make my project function well